Maury Microwave has earned a distinguished reputation in the RF and microwave industry through its unwavering commitment to precision, innovation, and long-term reliability. Since its founding in 1957, the company has evolved into a global leader, supporting critical advancements in high-frequency technologies across sectors like aerospace, defense, telecommunications, and semiconductor research.

Based in Ontario, California, Maury operates a state-of-the-art 90,000-square-foot facility that combines advanced manufacturing, R&D, and calibration services. As industries shift toward 5G, 6G, and satellite communication systems, Maury’s cutting-edge solutions remain essential for testing, validating, and fine-tuning next-generation electronic components and devices.

What Makes Maury Microwave a Standout in the RF Industry?

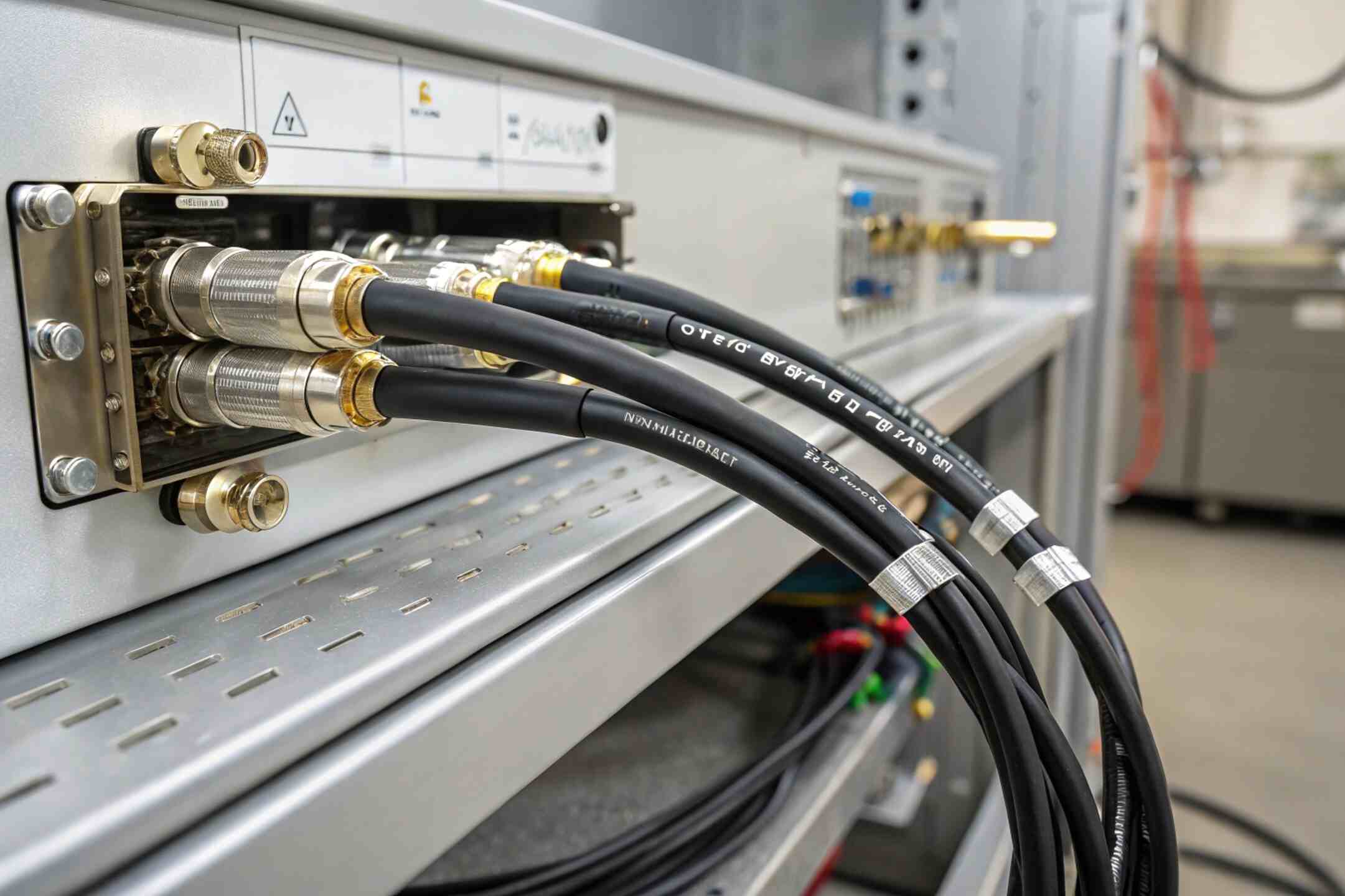

Maury Microwave is not just another component manufacturer—it is a complete solutions provider. By designing and fabricating calibration kits, measurement systems, precision adapters, and amplifiers, Maury helps engineers maintain accuracy in complex, high-frequency environments. Their solutions cater to routine laboratory testing, high-performance metrology, and fully automated production testing.

From coaxial and waveguide assemblies to software-integrated load-pull systems, Maury supports every stage of the RF product development cycle. Many of the company’s innovations, such as the Blue Dot Precision Connector and the 2.92mm connector, have become industry standards.

What Are the Key Capabilities and Services Offered by Maury Microwave?

Advanced Manufacturing with Precision:

Maury Microwave dedicates nearly 40,000 square feet of its facility to manufacturing and assembly. Utilizing cutting-edge equipment like CNC milling, wire electrical discharge machines, and honing systems, the company ensures every product meets the highest standards.

Precision is not just a promise—it’s measured. Maury employs:

- Coordinate measuring machines (CMMs)

- Laser micrometers

- Optical probes

- Air gauges

Each component goes through rigorous inspection to ensure its mechanical and RF integrity. This is especially crucial when working with frequencies up to 170 GHz, where even minor imperfections can cause signal degradation.

What Product Lines Does Maury Microwave Offer and What Makes Them Unique?

Overview Table: Maury Microwave Product Highlights:

| Product Category | Description | Frequency Range |

| Calibration Kits | High-precision kits for VNAs and systems | DC to 67 GHz+ |

| Precision Adapters & Cables | Coaxial and waveguide interconnects for lab and metrology use | DC to 110 GHz |

| Test Amplifiers (MPA) | Wideband, high-linearity amplifiers with built-in protection | 600 MHz to 26.5 GHz |

| Load-Pull Systems | Passive, active, harmonic, and pulsed load-pull tools | Up to 170 GHz |

| Noise Measurement Systems | Tools for noise figure and noise parameter testing | Up to 90 GHz |

| On-Wafer Measurement Tools | Probe stations for semiconductor device testing on 200 mm & 300 mm wafers | Up to 170 GHz |

How Does Maury Microwave Support Load-Pull and Device Characterization Technology?

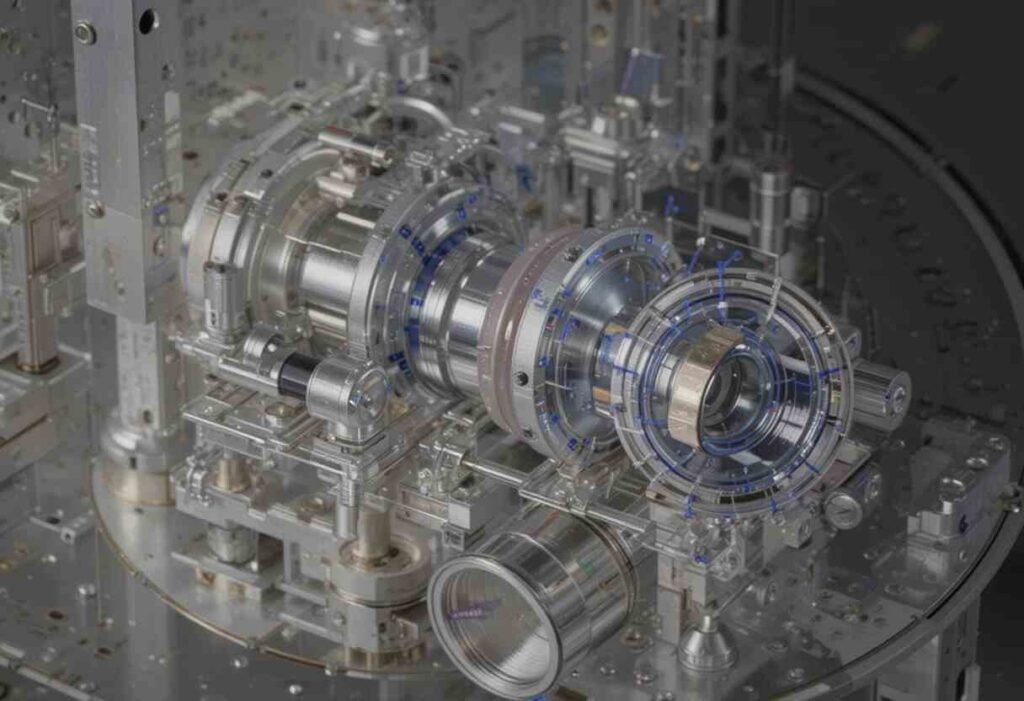

Maury Microwave has established itself as a global leader in load-pull measurement systems. These systems allow RF engineers to optimize active devices such as power amplifiers under real-world operating conditions.

Their systems include:

- Passive Load-Pull: Offers precise impedance control for linear device testing.

- Active Load-Pull: Used for nonlinear testing, dynamic signal conditions, and harmonic tuning.

- Harmonic Load-Pull: Extends frequency control for distortion-sensitive applications.

- Automated On-Wafer Load-Pull: Ideal for MMIC and transistor testing at wafer level.

Maury integrates its load-pull systems with intuitive software, enabling engineers to visualize impedance contours and performance plots in real-time.

How Does Maury Microwave Ensure Calibration Accuracy and Quality Standards?

In high-frequency testing environments, maintaining consistency and measurement traceability is not just important—it’s essential. So how does Maury Microwave uphold these standards across its product and service offerings?

Maury operates under ISO9001 and AS9100-certified quality management systems, reflecting their commitment to strict industry requirements. Beyond this, their calibration services comply with ISO/IEC 17025, ensuring that every calibration is traceable to national or international standards.

To further support their customers, Maury offers a full range of services including factory recalibration, custom calibration solutions, and instrument repairs. These services help extend the life of test equipment, reduce measurement errors, and ensure compliance in both commercial labs and mission-critical environments.

What Happens Inside the Maury Microwave Measurement and Modeling Lab?

Maury’s lab is where cutting-edge theories meet practical applications. From testing active devices under pulsed conditions to measuring nonlinear behavior at millimeter-wave frequencies, the lab supports a variety of advanced RF research projects.

Measurement Lab Capabilities:

| Measurement Type | Capability Specification |

| IV Curve Tracing | Up to 250V and 30A |

| S-Parameter Testing | Up to 170 GHz (CW), 67 GHz (Pulsed) |

| Noise Parameter Analysis | To 90 GHz with low-noise setups |

| Load-Pull (Passive/Active) | Up to 170 GHz |

| On-Wafer Testing | 200 mm and 300 mm wafers |

| Faraday Shielding | Reduces test noise and interference |

How Has Maury Microwave Driven Innovation Through the Decades?

Since its inception in 1957, Maury Microwave has driven progress in RF measurement science. Over the years, the company introduced several industry-firsts that improved test reliability and efficiency.

Examples include:

- First commercial connector gage kits for RF calibration

- Color-coded cable and connector solutions to prevent mismatches

- Smart amplifier systems that combine gain, protection, and control

In 2021, Maury strengthened its portfolio by acquiring dBmCorp, adding advanced signal generation and noise source technology to its capabilities. This move positioned the company even closer to the core of emerging RF research fields like satellite telemetry, IoT, and 6G networks.

Which Industries Rely on Maury Microwave’s Expertise and Technology?

Aerospace & Defense:

Government contractors and aerospace firms use Maury’s amplifiers and calibration systems to test avionics, radar, and electronic warfare components. The rugged build quality and wide frequency range make them ideal for mission-critical applications.

Academia and Research Labs:

Universities and R&D institutes depend on Maury’s measurement tools for prototyping and semiconductor material research. Their systems support new frontiers such as metamaterials, MEMS, and high-power GaN devices.

Semiconductor and Foundry Services:

On-wafer testing and behavioral modeling are essential in semiconductor development. Maury’s probe stations, amplifier systems, and tuner products allow foundries to model nonlinear behavior and validate die-level performance before production.

How Does Maury Microwave Deliver Customer-Centric Support and Services?

Maury’s focus is not limited to product delivery. Their technical support, training programs, and engineering consultations ensure clients get the most from their investment. Customers can request:

- Factory calibration services

- Custom measurement setups

- Software integration with existing lab equipment

- Failure analysis and repair

They also offer detailed documentation and online resources to guide users through product use and calibration steps.

How Is Maury Microwave Positioned to Lead in Next-Gen Wireless Technologies?

As wireless technologies push beyond today’s limits, Maury Microwave is already adapting to meet tomorrow’s needs. But how is the company preparing for the shift toward next-gen communication systems?

Through continuous upgrades in bandwidth support, software integration, and device compatibility, Maury is laying the groundwork for breakthroughs in the RF and microwave space. Their systems already support operations up to 170 GHz, making them highly relevant in research and deployment of future wireless infrastructure.

Which Future Applications Will Maury’s Solutions Enable?

With advanced capabilities already in place, Maury Microwave is well-aligned to support emerging technologies such as:

- Low-orbit satellite constellations for global connectivity

- Non-terrestrial networks (NTN) enabling communication across land, air, sea, and space

- Ultra-wideband sensing and radar used in defense, health monitoring, and smart environments

- Smart infrastructure and automotive radar that power connected vehicles and intelligent transportation systems

As industries aim higher and go farther, Maury’s expertise and solutions will play a vital role in shaping the wireless systems of tomorrow.

FAQs:

What makes Maury Microwave different from other RF solution providers?

Maury Microwave stands out for its deep vertical integration—combining in-house R&D, manufacturing, and calibration under one roof. This allows them to deliver consistent quality, rapid innovation, and personalized support for complex RF testing needs.

Can Maury Microwave equipment handle sub-THz and future 6G technologies?

Yes, Maury’s solutions support frequencies up to 170 GHz, making them ideal for emerging applications such as 6G, sub-terahertz research, and non-terrestrial networks (NTN). Their systems are frequently used in early-stage prototyping and academic research, pushing the limits of wireless technology.

How does Maury Microwave ensure long-term accuracy in test systems?

Maury offers ISO/IEC 17025-compliant calibration services along with robust factory recalibration and repair programs. These services help maintain long-term accuracy, measurement traceability, and equipment longevity in mission-critical environments.

Is Maury Microwave suitable for small labs or only large enterprises?

Maury supports a range of users—from large defense contractors to university labs and startups. Their product lines are categorized by performance and budget tier, making them accessible for small-scale research as well as high-throughput production environments.

What kind of training and support does Maury provide after purchase?

Maury offers in-depth technical support, documentation, and both on-site and virtual training. Their engineers also assist with custom test setups, integration, and application-specific configurations to help customers get the most from their investment.

Conclusion:

Maury Microwave has consistently proven itself as a foundational force in the RF and microwave industry, providing precision-engineered solutions that meet the evolving needs of global technology leaders. With a comprehensive product lineup, future-ready measurement systems, and unmatched support, Maury enables innovation across critical sectors including aerospace, semiconductors, and advanced wireless communication.

As industries shift toward 6G, satellite networks, and sub-terahertz systems, Maury Microwave’s continued investment in high-frequency design and calibration excellence ensures it will remain a trusted and forward-looking partner for decades to come.

Related post: